William Ross, 9604 Belmont Ave, KC, MO 64134

Made in America since 1976!

Our knives fit Woodmaster®, Powermatic®, Foley Belsaw®, RBI®, Sears®, Jet®, Grizzly® planer Molders as well as multi headed molders, and corrugated shaper cutters. All 1/4” and 5/16” corrugated are $12.50 per inch, smooth back knives are all priced at $13.95 per knife inch. All 1/8” knives $10.95 inch. William and Hussey knives are priced at $10.95 per knife width inch. Eight inch knives are sold in sets of three. Holding gibbs are included.

Introducing the patent pending TRIM SANDER!

What does the TRIM SANDER do? When wood is run through a molder there is always knife marks and small imperfections left on the wood. Here are some of the reasons.

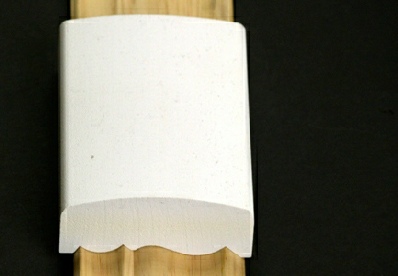

You can address these problems by simple ignoring the flaws. However, be aware these issues will become much more pronounce during staining or painting leading to poor customer satisfaction, or you can properly prepare the molding by sanding. (See Picture)

The next question is “How do you sand a contoured piece of wood without changing the pattern and spending large amounts of profit killing time on the job?” There are several current “solutions” available these include Sponge Sanders (link to video).

These are very slow, can change the pattern and can leave “finger grooves” in the wood that shows up after staining. Another “solution” uses various shaped blocks and rods (link to video) which are even more tedious and time consuming than sponge sanders. Many use what are known as mop sanders. These are expensive and will nearly always change the shape of the molding by sanding the tall parts down and not sand the tighter areas at all. All these have another flaw in that the molding will be slightly different from stick to stick depending on pressure applied.

How does the patent pending TRIM SANDER address these short comings? The TRIM SANDER is cut on CNC equipment using the original DXF code that we use to cut your molding cutter. (Show the TRIM SANDER) This will create perfect matching of the sander to the trim allowing you to get into the tight areas without over sanding the taller sections. NO DISTORTION OF SHAPE! The TRIM SANDER is much quicker than blocks and sponges and much more cost effective than a mop sander. This makes the TRIM SANDER truly the best sander regardless of price.

What will this mean to YOUR molding business? The most important benefit is higher quality product allowing for premium pricing and more PROFITS. This also sets you apart from the other molding companies, guaranteeing more repeat and referral work and greater customer satisfaction. Another way to build profits and customer loyalty is to sale the Trim Sander to your customer. They can use the Trim Sander to smooth nail holes, true uneven joints and touch up small flaws. A win/win for you and your client.

The Trim Sander is made in our shop out of EPS. This is similar to “Styrofoam” but is 3 times denser and 7 times less compressible. It is capable of sanding thousands of feet of molding, uses replaceable sanding sheets and is reusable. The Trim Sander is shaped to easily fit in your hand for ease of use.

So what does this cost? When ordering with a cutter only $24.95 and it comes with both coarse and fine sand paper (additional paper is available).

FOR A LIMITED TIME YOU CAN PURCHASE THE TRIM SANDER FOR JUST $19.95 WITH YOUR KNIFE ORDER….CALL TODAY!